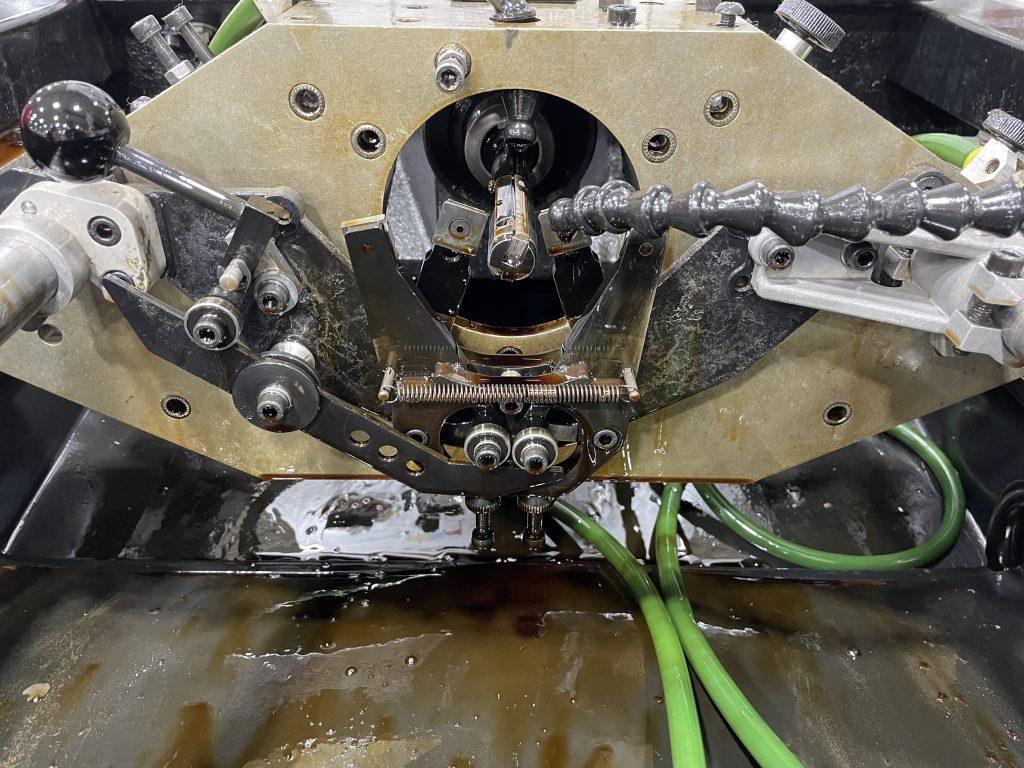

Horizontal Honing Machine

The first name in precision-machined products, Firstar provides custom honing services with superior accuracy and repeatability. Our versatile honing systems offer a maximum stroke length of 6.7” or power stroking at 4.0” lengths, capable of accommodating a wide range of production honing jobs.

Horizontal Honing Capabilities Including Power Stroke Honing

- Maximum stroke length – 6.7”

- Power stroke honing up to 4.0”

The Honing Process Explained:

The Honing Process Explained:

Honing is a unique machining service that Firstar uses to improve the geometric shape, surface finish, and overall precision of a workpiece. The machining process involves the use of abrasive stones or tools to remove small amounts of material from the surface of the workpiece.

We can perform precision honing on virtually any component interior with cylindrical or spherical surfaces – perhaps the most common example being the inside cylinder bore in an engine block. Our highly accurate honing capabilities allow us to achieve extremely tight tolerances and a smooth surface finish repeatably from one component to the next.

Firstar is backed by extensive honing experience in a wide range of applications including automotive, aerospace, hydraulics, and industrial equipment, where tight tolerances and high-quality surface finishes are essential for the performance of the final product.

- Workpiece Preparation – We begin with preparing the workpiece by machining it to a close approximation of the final desired dimensions. This initial machining may leave behind small imperfections, such as tool marks or irregularities in the surface.

- Honing Tool Selection – Honing tools, typically abrasive stones or diamond-coated sticks, are selected based on the specific application and desired finish. The size and grit of the stones are chosen to match the workpiece material and requirements.

- The Honing Process – The honing tool is attached to a honing machine, which can be manual or automated. The tool is then inserted into the workpiece and moved back and forth, typically in a rotational motion. As the tool moves, it removes small amounts of material from the workpiece surface.

- Careful Material Removal – The abrasive action of the honing tool gradually removes high spots, surface irregularities, and any remaining machining marks. This results in a more accurate and smoother surface finish.

- Precise Control of Size and Geometry – Honing is also used to control the size and geometry of the workpiece. We can make precise adjustments to dimensions within tight tolerances to meet even the most challenging geometric specifications.

Improved Surface Finish – One of the key benefits of honing is the smooth, even surface finish. We can also hone unique surface features. A common example is a honed crosshatch pattern on the workpiece surface, often used for applications, like engine cylinders and hydraulic systems, because patterning helps lubrication cling to the surface, thus reducing friction.

The First Name in Precision Machining and Honing Services

Firstar Precision is one of America’s leading providers of quality CNC machining and precision honing services. We are proud to say we are now a 100% employee-owned company still founded on the cornerstone of outstanding quality and customer service.

Firstar consistently takes on the challenging contract manufacturing jobs that few providers in the industry can accommodate. We continue to expand our service offerings and search for better ways to serve our customers, maintaining our status as the authority for precision-honed components. Based out of Brunswick, Ohio since 2000, Firstar is an ISO 9001:2015-certified American manufacturer.