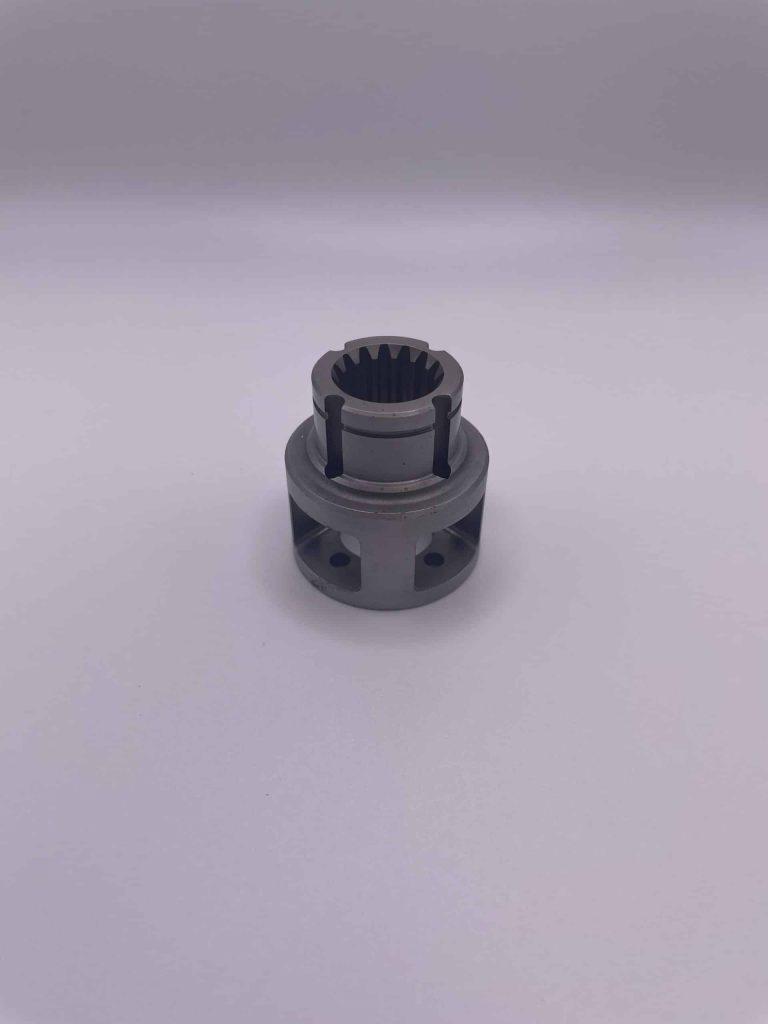

CNC Gear Shaper

The first name in precision-formed and machined components, Firstar offers CNC gear shaping, hobbing, and cutting services. CNC gear processes are commonly used in various industries where precise gears are required, such as automotive, aerospace, robotics, and industrial machinery manufacturing.

Precision Gear Shaping Services – AGMA Class 10 Gears

The CNC Gear Shaping Process Explained:

The CNC Gear Shaping Process Explained:

CNC gear shaping is a manufacturing process used to produce gears with high precision and accuracy. It is a variant of gear shaping, a traditional machining method, but with the added advantage of computer numerical control (CNC) technology for greater automation and control over the process.

Tooling

Once we have the finalized gear design, we select special cutting tools (called shapers or cutters) that match the required gear profile and tolerances. Often standard tooling can be used, while many specialized gearing applications may require custom-fabricated tooling. These cutters have the inverse shape of the gear teeth to be produced.

CNC Programming and Setup

We utilize a CNC program based on the 3D-model and/or specifications of the custom gear. This program precisely guides the CNC gear shaping machine to precisely control the cutter’s movements and the gear blank’s rotation. The gear shaping machine itself is set up with the gear blank, which is typically a disc or cylinder of metal. The blank is securely mounted on a spindle that can rotate it while the tooling moves across its surface and generates the gear profile.

Shaping Process

During the machining process, the CNC gear-shaping machine precisely controls the cutter’s movement to cut the gear teeth into the blank material. The cutter engages with the blank, removing material to form the gear teeth. This is done gradually, with multiple passes, until the final tooth profile is achieved.

The CNC Gear Hobbing Process Explained:

CNC gear shaping is a manufacturing process used to produce gears with high precision and accuracy. It is a variant of gear shaping, a traditional machining method, but with the added advantage of computer numerical control (CNC) technology for greater automation and control over the process.

Tooling

Once we have the finalized gear design, we select special cutting tools (called shapers or gear cutters) that match the required gear profile and tolerances. Often standard tooling can be used, while many specialized gearing applications may require custom-fabricated tooling. These cutters have the inverse shape of the gear teeth to be produced.

CNC Programming and Setup

We utilize a CNC program based on the 3D-model and/or specifications of the custom gear. This program precisely guides the CNC gear shaping machine to precisely control the cutter’s movements and the gear blank’s rotation. The gear shaping machine itself is set up with the gear blank, which is typically a disc or cylinder of metal. The blank is securely mounted on a spindle that can rotate it while the tooling moves across its surface and generates the gear profile.

Shaping Process

During the machining process, the CNC gear shaping machine precisely controls the cutter’s movement to cut the gear teeth into the blank material. The cutter engages with the blank, removing material to form the gear teeth. This is done gradually, with multiple passes, until the final tooth profile is achieved.

Inspection and Quality Control

After the machining process is complete, we thoroughly inspect the gear shape and tolerances to ensure the end product meets your required specifications using the following equipment:

- Gleason 175 GMS analytical gear testing machine

- Vari-roll gear tester

CNC gear processing offers several advantages over traditional methods:

- Higher Precision and Complexity – CNC technology allows for extremely accurate gear production with tight tolerances. It can create complex gear tooth profiles that may be difficult or impossible to achieve with other methods.

- Manufacturing Flexibility – It can be used to create a wide range of gear types, including spur gears, helical gears, bevel gears, and internal gears.

- Higher Speed and Efficiency – CNC machines can produce gears more quickly and consistently than manual methods.

- The Advantages of Automation – CNC gear machines can be programmed to run unattended for extended periods, increasing productivity.

The First Name in Precision CNC Gear Shaping Services

Firstar Precision is one of America’s leading providers of quality CNC gear shaping services. We are proud to say we are now a 100% employee-owned company still founded on the cornerstone of outstanding quality and customer service.

Firstar consistently takes on the challenging CNC milling jobs that few providers in the industry can accommodate. We continue to expand our service offerings and search for better ways to serve our customers, maintaining our status as the authority for precision-milled CNC components. Based out of Brunswick, Ohio since 2000, Firstar is an ISO 9001:2015-certified American manufacturer.